March 19, 2021, the "2021 China Lithium Battery Industrial Weighing Conference/Business Dinner" of General Measure Technology was successfully accomplished. The meeting focused on the application of industrial weighing indicators and related technologies in the lithium battery industry, as well as shared the latest product technology and application cases.

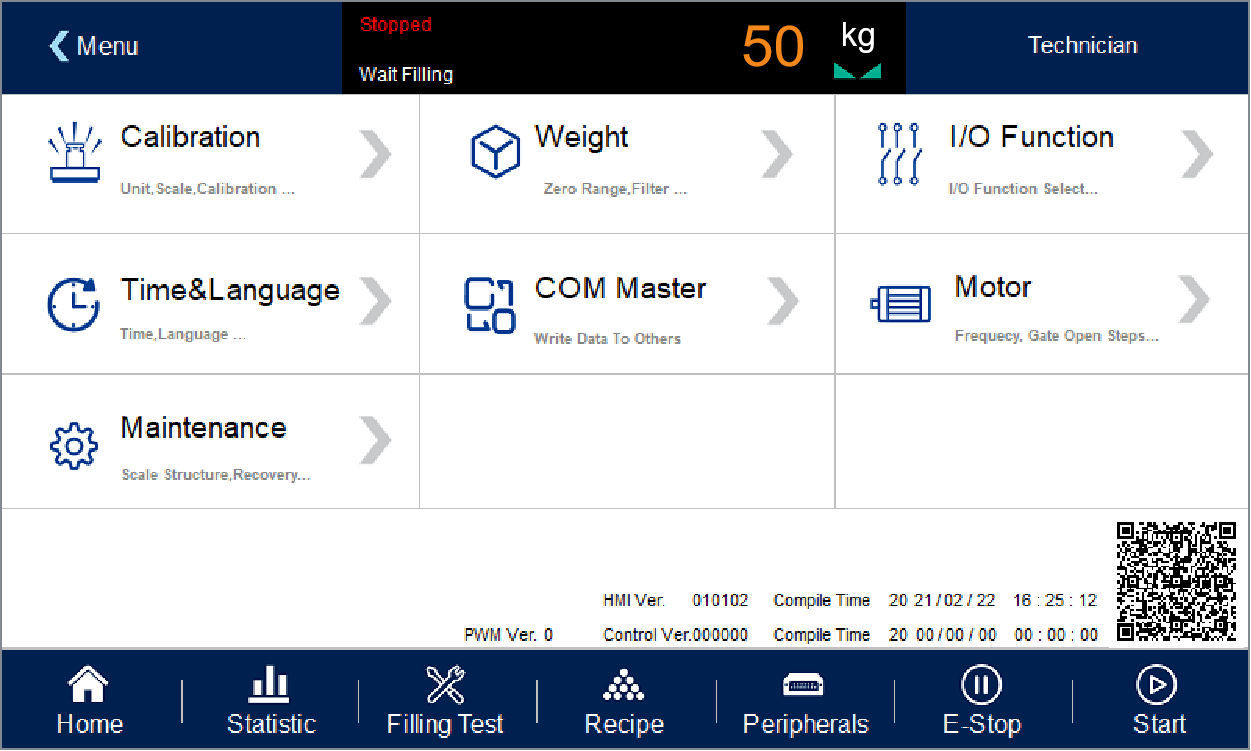

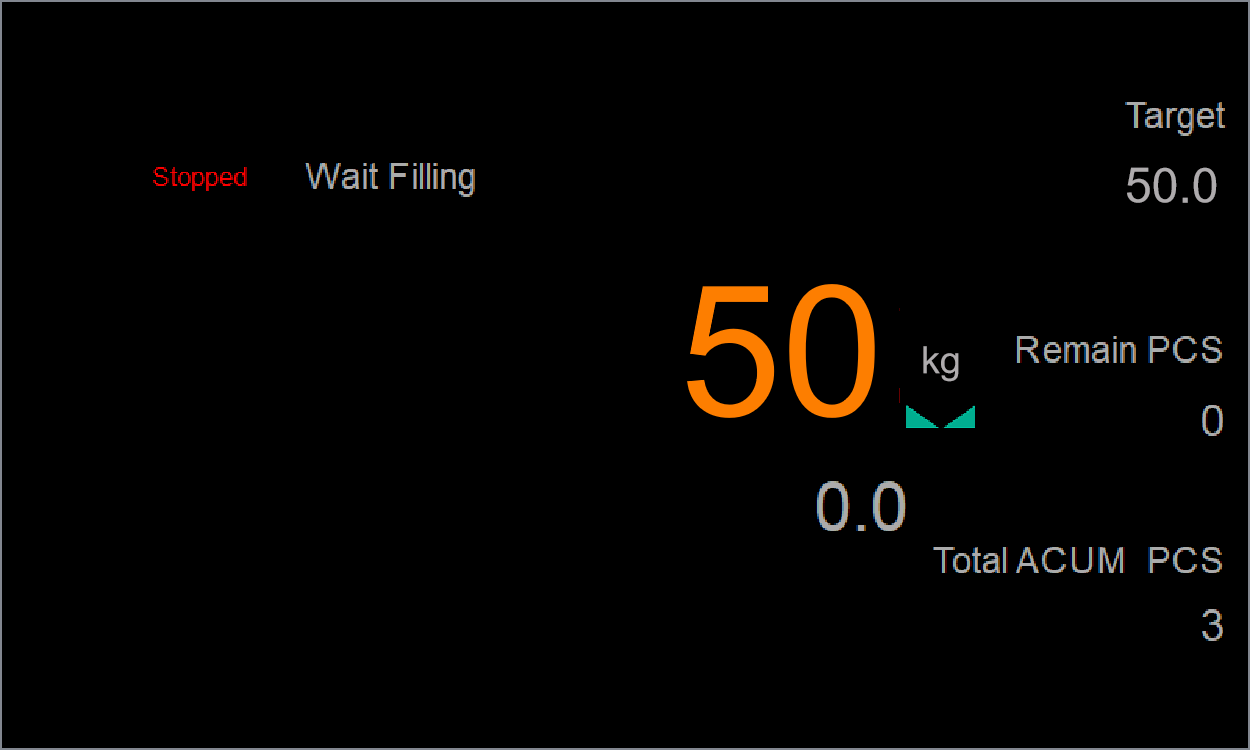

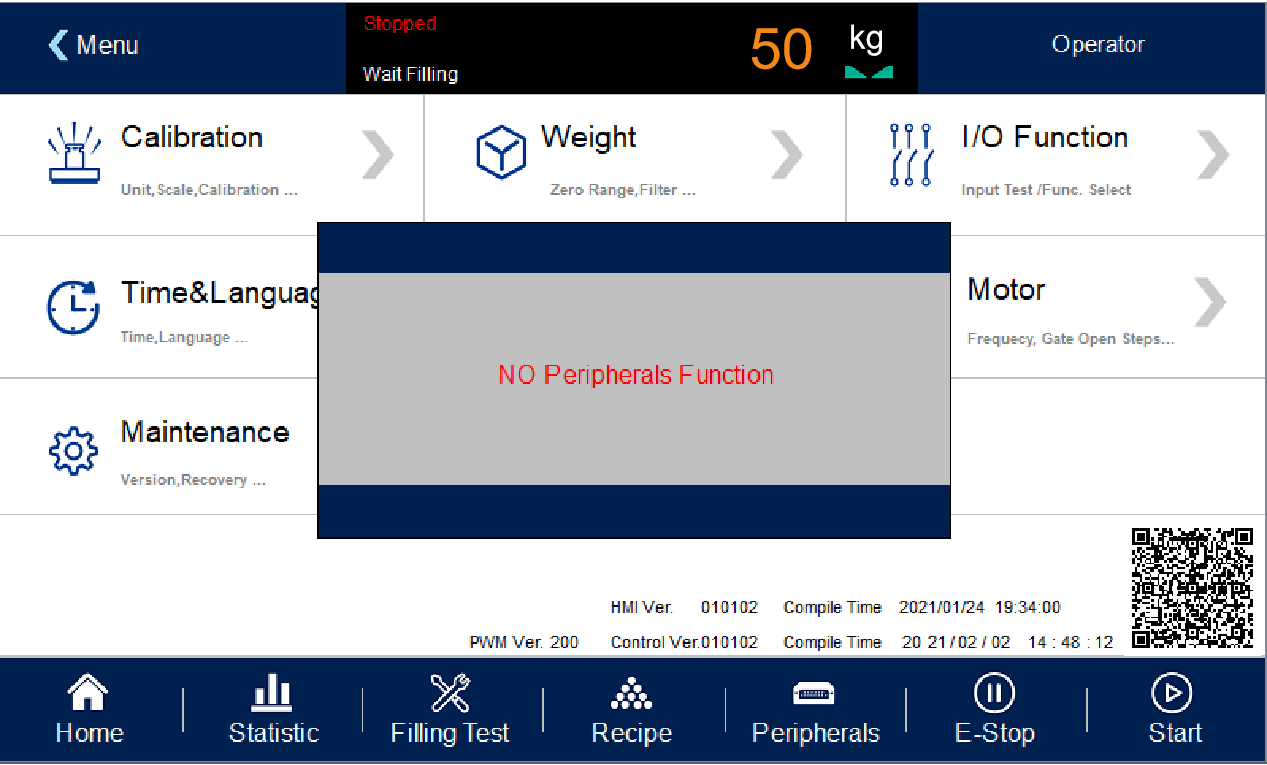

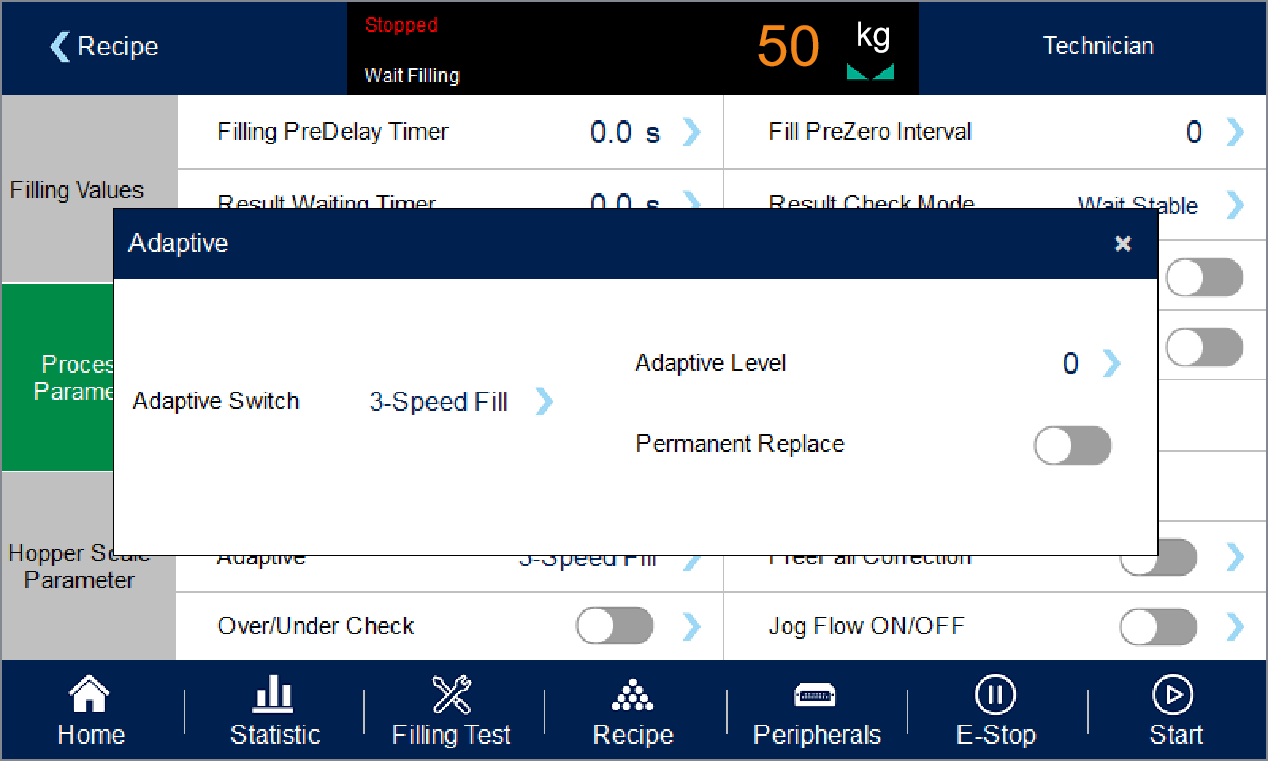

General Measure was pleased to invite our clients and potential clients to attend, such as the engineers, sales or purchase managers of Ross, Ongoal Technology, Famsun Group, and so on. During the conference, the domestic sales director (China) shared the GM company profile including history, business sector, and productivity. The R&D manager demonstrated the products and applications and shared the new weighing technology like second-generation vibration cancellation filter, Bluetooth connecting to mobile app for parameter setting and monitoring. Also, GM’s panel-mounted weighing indicator, DIN rail mounted weighing transmitter and touch screen weighing controller in parts of the lithium battery production line were displayed. Clients showed their interest in the products and applications. The trend of weighing technology in the lithium battery industry was discussed.

|  |

Thanks to all attended clients, General Measure is looking forward to working and growing up together with you.

|